The Future of Knowledge Work: Software as the New Assembly Line

The birth of the modern assembly line

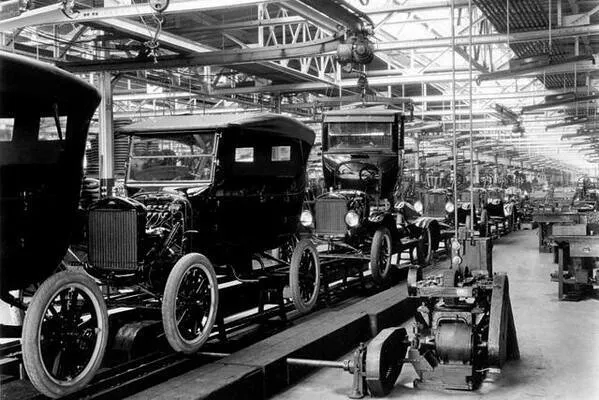

Henry Ford had a problem. He dreamed of making cars that average consumers could afford. Even though the Ford Motor Company found some success early on with the Model A, its manufacturing process just couldn't crank out cars efficiently enough to lower the price tag. The Model N was meant to be a lightweight, low-cost car for the masses, but at $500, it was still too pricey for most. Ford realized he needed a new approach to production if he wanted to pull off his vision.

Ford found his answer during a trip to Chicago's Union Stock Yards. There, he saw workers systematically breaking down animal carcasses into standardized cuts. In his autobiography, Ford wrote, "The idea for the assembly line came in a general way from watching the Chicago packers disassemble beef carcasses on overhead trolleys."

Ford was inspired by the disassembly of a carcass and used the principle for the assembly of the Model T. He broke down the Model T into 84 parts and had the chassis move down a line while workers each added their component. This division of labor meant each person could focus on one task, and the standardization meant each Model T came out the same.

The results were transformative. Build time for a Model T dropped from nearly 12 hours to 93 minutes, and costs plummeted. Before, Model N production had peaked at around 8,000-10,000 cars per year. Now, Ford was cranking out nearly 250,000 Model Ts annually!

At its heart, the assembly line is just a system for coordinating work that can apply to any complex project. It breaks down the project into small, standardized steps, sequences the right tasks for each specialized worker, and brings everything together in the end. While building Model Ts, it meant turning parts into full cars. But the same logic works for designing buildings, developing software, or creating marketing campaigns.

The white-collar assembly line

So how did the assembly line for knowledge work function during this era?

Imagine the business operations within a company manufacturing parts for Ford. Let's say a sales rep needed to produce a quote for a new type of ball bearing.

The sales representative would summon a typist from the typing pool—typically a group of women assisting all departments. He would dictate a memo outlining the specification and request help from the engineering department.

The typist would generate several carbon copies of the memo: one for internal records, one for company records, and one to send to engineering. A mail clerk would then hand-deliver the memo to the engineering department.

Engineering would prioritize the request and assign an engineer to evaluate the specifications. The entire communication process continued in this manner: typists, carbon copies, and mail clerks. This workflow, transforming an idea into a manufacturing quote, constitutes the white-collar equivalent of an assembly line in the early 20th century

The assembly line modernizes

Fast forward to today, and our factories now have robots, and offices don't have typing pools or mail clerks. But peer into the software stack, and you'll see vestiges of the prior era in the applications that have taken their place.

We now communicate using tools such as email and Slack rather than typists and carbon copies. We maintain records in CRM software rather than physical filing cabinets. Various applications shuffle work-in-progress between departments, track progress, and facilitate the coordination required for workers to produce the final product.

How well does your assembly line adapt?

No process remains efficient without ongoing refinement and enhancement. Products and problems evolve, rendering initial designs and specifications obsolete. Inspired by Edwards Deming's principles of statistical quality control, post-WWII Japanese manufacturers like Toyota pioneered the philosophy of kaizen or continuous improvement.

They realized that implementing incremental changes to the system design, training, equipment, and methods can lead to substantial benefits over time. Factories following the principles of lean manufacturing add pathways, tune machines, and make minor modifications to revise their assembly lines.

The rise of Biz Ops

The modern company's digital assembly line hums not with the churn of machinery but with the silent exchange of information between software systems. A factory would typically utilize Andon cords, a system that helps operators identify problems with machinery or quality control, and gemba walks, a practice where managers go to the production floor to observe. In our knowledge assembly line, we employ Slack channels and conduct review meetings to achieve similar objectives.

These complex software ecosystems require care and feeding, spurring the rise of new roles focused on monitoring and optimizing them. Known as sales ops, marketing ops, and the more general “biz ops,” these groups help departments run as efficiently as possible. Job listings for positions like "Marketing Operations Manager" and "Sales Operations Analyst" have skyrocketed over 100% in the past five years, according to Indeed and ZipRecruiter. Equiteq projects the Salesforce ecosystem, which includes 124,000 experts and 350+ resellers, will expand 3.5 times over 2020 levels by 2026.

Low-code meets process management

Not every process can support dedicated ops roles or adding technical staff. This demand has fueled a boom in user-configurable software like Airtable, Coda, and Notion, which promise low-code or no-code ways to manage business processes. The low-code/no-code market is estimated to be $25B, growing at 28% annually. Starting from templates, teams can build custom workflows that suit their needs and adapt to their requirements. After all, an ill-fitting software solution hampers productivity like an oversized suit.

However, low-code and no-code tools have limitations. Beyond a certain point, designing interfaces or writing formulas requires technical skills. This often means needing ops experts or consultants to optimize the tools. In reality, poorly designed and unsupported "apps" built on these platforms have left many companies with siloed data and fragmented processes.

The future of software is bespoke

A new age of AI-powered software is emerging. One where AI develops and tailors apps to meet our needs—on demand. Visionaries like Ford knew progress depends on the ability to optimize constantly. Now, AI could provide each of us with a dedicated dev team that continually refines solutions in response to how our work evolves. It's as if every team will have its own R2-D2—an AI astromech—customizing our digital X-wings at a moment's notice.

AI will build the apps we've wished for but never had the means to create—apps crafted for niche use cases, tailored workflows, and personal preferences. AI makes the bespoke and customized not only possible but also scalable. No longer will businesses be forced to fly their starfighters with the software equivalent of mismatched parts and ill-fitting upgrades.

At boxcars.ai, we're working to invent a future where AI will stitch digital solutions as tailored as any Savile Row suit. Follow our newsletter for updates and demos. To learn more, contact us at hi@boxcars.ai.

Want these insights delivered? Subscribe below.